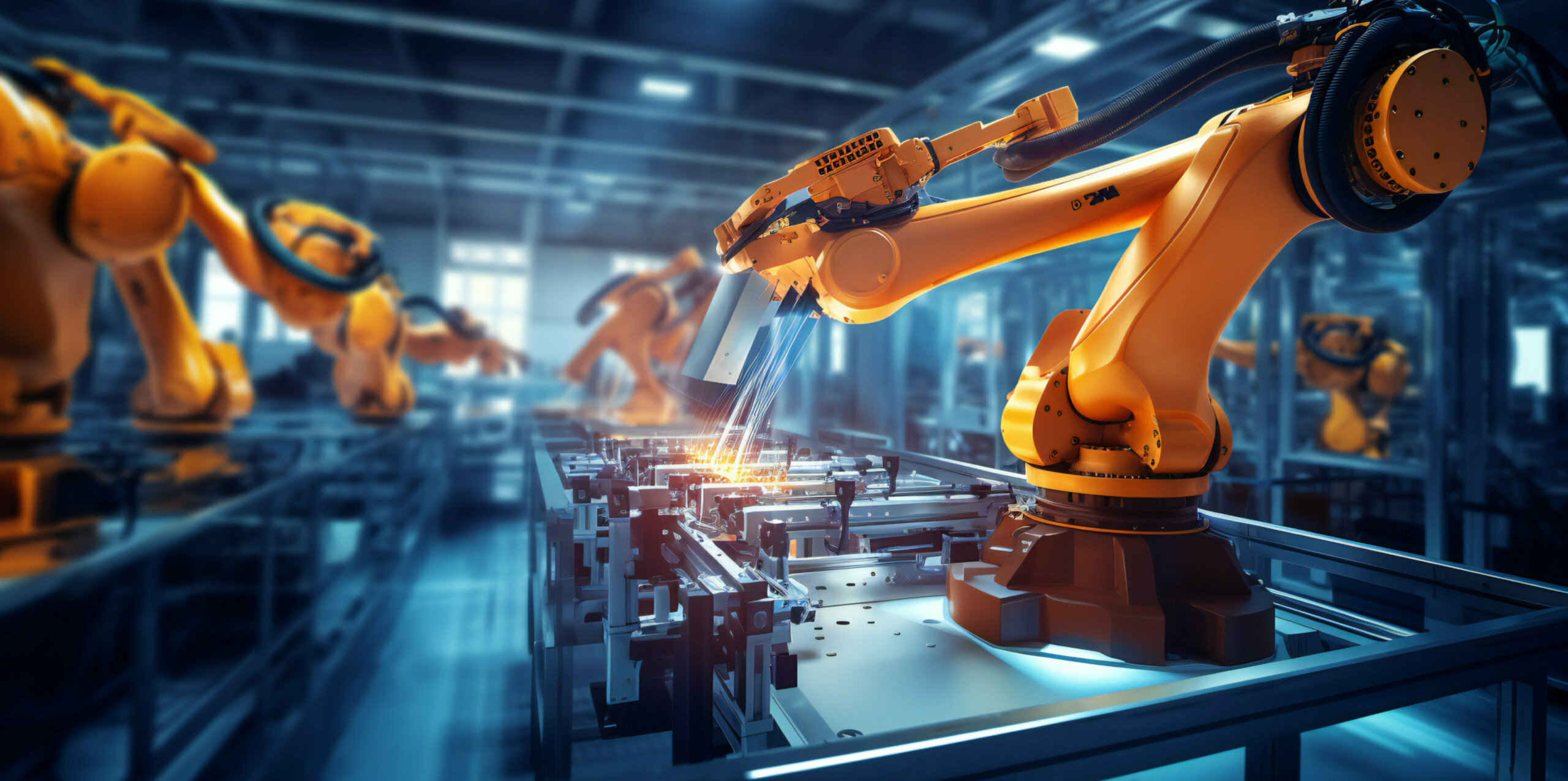

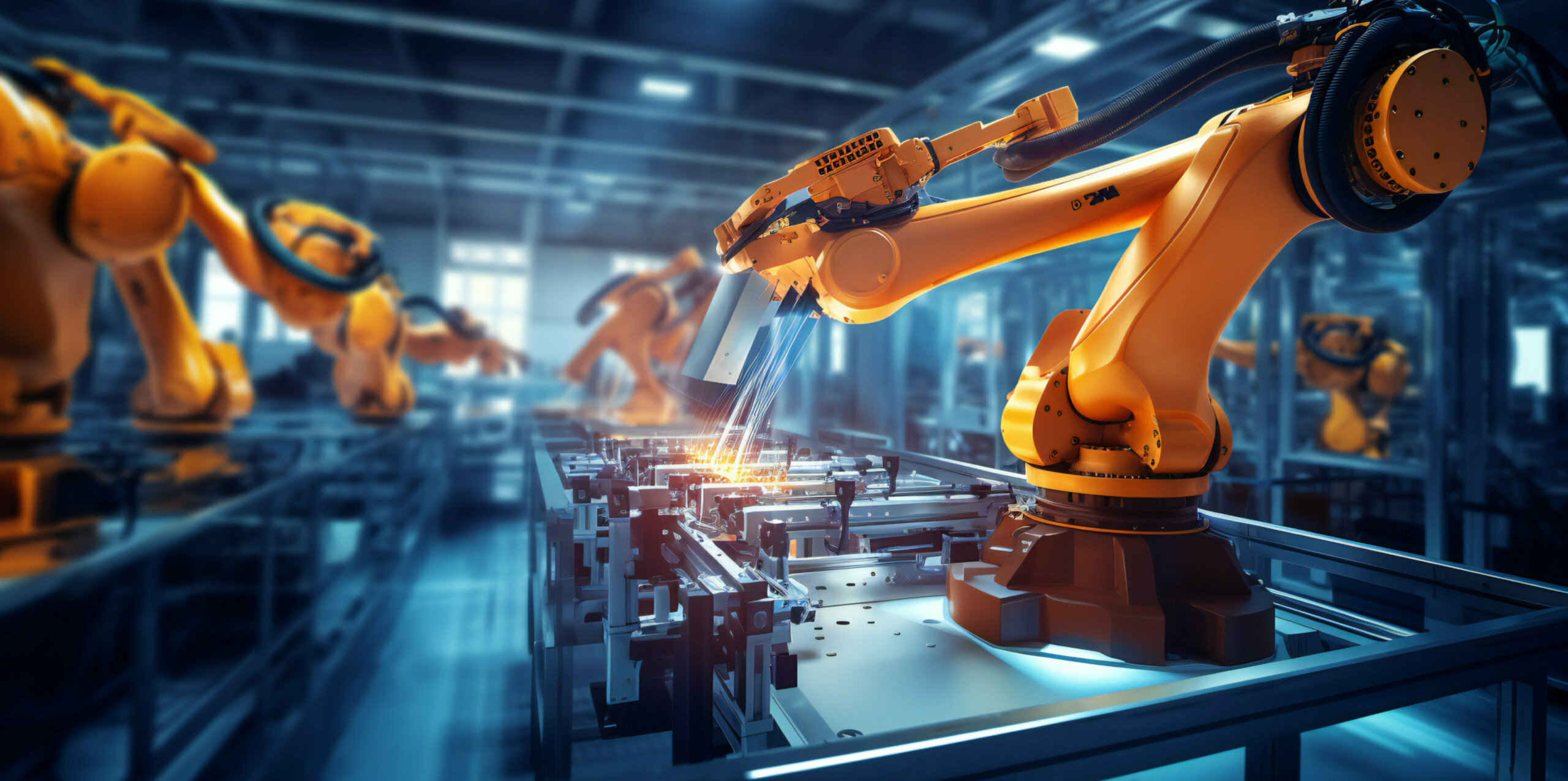

Machines can no longer be viewed individually, but are part of the overall context of production. In order to optimally utilize the machines and accelerate the manufacturing processes, this interaction between the machines must also be reflected in the entire data flow. Each machine makes its data available for central analysis. This helps identify bottlenecks and detect deviations from normal values so that errors can be corrected during scheduled maintenance before they lead to failures. Various protocols such as OPC UA or MQTT can be used. We accompany you throughout the entire process, from identifying use cases to selecting suitable solutions and implementation.

smartIoT Machine Connectivity includes the concept of processing data about incoming raw materials and outgoing finished goods. This data is processed synchronously with the data from the production facilities. It describes the connection of machines, machine data, master data and production processes.

The growing number of connected devices, cheaper sensor technologies, and the expansion of IoT technology and products are enabling companies to gain better production insights.

The central display of machine sensor data in real time leads to easier control, fewer downtimes and higher machine utilization. Using a web-based dashboard, the data can be displayed not only on a screen on the machine, but also on mobile devices.

To connect the machine, direct access to the control data with OPC UA is often possible. Alternatively, it is also possible to retrofit the machine with additional hardware (e.g. PLCnext Control). By integrating the dashboard into SAP, seamless integration into existing processes is achieved. We support you so that your processes run smoothly and capacity bottlenecks are eliminated before they arise.

In many use cases, a historical evaluation of the data is also important in order to identify possible problems at an early stage and to be able to optimize the processes. Current approaches such as predictive maintenance or predictive analytics in particular require an appropriate database to optimize processes using artificial intelligence in order to be able to make predictions for the future. However, looking into the past also helps, for example to detect when threshold values have been exceeded. These exceedances can also be reported directly to the responsible employee.

The hub of your data

The topic of integrating different worlds and software solutions is certainly a challenge for your company. As part of digital transformation, stable SAP systems require functioning integration and connections to different systems and machines. With the smartERP Connector you have an innovative and highly flexible tool with which you can easily integrate your systems both in the company and in cloud applications.

to the smartERP Connector